Conformity?

Related to quality there are always two basic goals: conformity and customer satisfaction. Conformity is the fulfillment of specifications, laws, regulations and any other contractual obligations. The customer satisfaction is reached by constantly providing not only “conforming” goods but also by fulfilling the expectations of the customer as well.

Let me stress once more that conformity is not only a goal but also a contractual obligation. Why? Because the on both sides: customer and supplier, there are common elements that serve as the base for the contract. For the customer the request for quotation and related documents define the conformity requirements. For the supplier, the conformity and the offered price go hand on hand.

You know this principle as consumer. You buy products with the intention to fulfill a need (basic or not) and your perception or degree of satisfaction goes through two main stages:

- At the first use, if the product does what it is supposed to, you have at least no regrets for buying. It works.

- After frequent use your satisfaction grows if the product keeps the expected functionality, reliability and perhaps provides even more functions and features as originally thought. Or it goes down if you feel disappointed.

But what happens if the product doesn’t work as expected? What if the functionality was bad and lower or worse than the performance of similar products? You would immediately agree with me that the product should be rated as “poor in quality”. You would even want to officially file a complaint hoping to get your money back.

Now, if we think of the best possible case, how would you feel if you had the certainty that every product you buy, works fine and fulfills at least the basic product requirements? I know, it would be wonderful!

Well, the carmakers think exactly the same. Therefore, along with the price offer, they require the written confirmation that you can manufacture and deliver the product as required. The official name given to this “request” is “feasibility confirmation” or “feasibility commitment”. The IATF16949 states: “the organization shall ensure conformance of all products and processes, including service parts and those that are outsourced, to all applicable customer, statutory, and regulatory requirements”.

Requirements

Most of the carmakers require not only that all suppliers get certified in IATF16949, but also demand compliance to additional requirements called CSR or Customer specific requirements. These CSR are related to the quality management systems and are written or defined with the same structure as the ISO9001/ IATF16949 standards (in chapters and general content).

Additionally to the requirements on the quality management system, some customer have supplier quality manuals, logistic requirements, detailed specifications for materials, testing, validation and many other technical standards to consider. Normally, the original text and complete specifications are only available at the customer internet portal and must be downloaded one at a time. The most important ones are called in one or more of the following documents: RFQ (request for quotation), SOR (statement of requirements), CSR, drawings, etc. and then, relevant for the contract.

If you want to really comply, you have to get, read and evaluate all related standards before making an offer. If you fail and miss important requirements you take the risk to either deliver nonconforming goods or, be caught by the customer and be legally compelled to honor your contract and forced to comply to ALL specs at the offered price. No price increase will not be allowed due to an omission.

So, how can you make sure that ALL requirements are fulfilled?

Feasibility analysis

The answer is: you need to define an appropriate process and strictly follow it.

You may recall the points discuss in the post “request for price and pricing”: in your quality management system there must be business processes which address your customers’ needs and enable your company to comply with all their requirements (you can also read the post about QMS).

Today we will only focus on the feasibility and consider:

- Scope,

- feasibility analysis,

- feasibility commitment

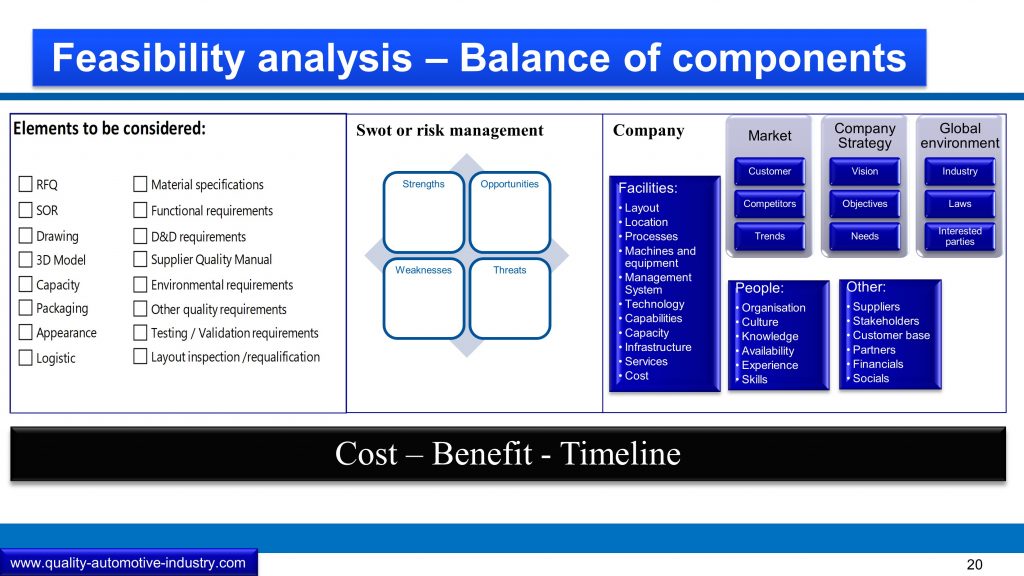

As quick reference you can take a look at the image below. These are the main components of the feasibility analysis.

Feasibility - Process flow

Many companies have a team of professionals who work together to analyze the customer information-package sent with the RFQ. Such companies also have personnel assigned to monitor the CSR either at the internet page of the customer or at the internet page of the IATF. The CSR’s are read, understood and the individual requirements are recorded in a matrix and/or data bank with the action taken to fulfill it, the related business processes and the documents used to record results. Other companies hire IT-Services to monitor changes, find gaps and suggest actions to comply.

However they do, the feasibility cannot be fully confirmed by only reading the requirements. Of course, the first step is to fully identify and understand the customer requirements, ALL of them. Only when you have done so you can proceed with the real feasibility analysis. Please be aware that there are many ways to successfully perform a feasibility analysis and I do not pretend to prescribe how you should do it. You can consider this a piece of advise. This is my proposed method and i have used it to establish, implement and maintain an ad-hoc processes for the companies I have worked for. It has helped them evaluate the potential of projects and acquire important business with the main carmakers and confirming feasibility with a high degree of certainty. Perhaps through a mix of 23-year-experience in different areas like purchasing, sales, project management, engineering and quality, and the knowledge gathered becoming an auditor on ISO9001, ISO19011, ISO14001, ISO/TS16949, IATF16949 and VDA6.3 , I got the °eyes” of the customer and the perspective of the suppliers. I know how difficult it is to comply to the requirements related to product, testing, tight tolerances, capability, capacity, etc.

In this proposal there are only 3 big steps:

- Preparation. All available data (known prior to the RFQ) must be assessed and deemed feasible as BEST PRACTICE. If you know your strengths, capabilities, limitations, weaknesses and define accordingly risk management and improvement techniques, you may proceed to the next step. As reference you can go back to the image of the Feasibility components.

- Assessment. Once you receive the RFQ your main focus should be ALL customer, project and product related data. The main task is to COMPARE and discover GAPS. If there are no gaps you can go for with certainty proceed to step 3. If there are gaps make a risk analysis and conceive actions to treat the risks. Perform a cost-benefit analysis and consider in your financials the manufacturing costs, all other cost drivers and the actions required to minimize the risks, guarantee compliance. Set a target or expected price (after negotiation) and project the results for the life of the project. Keep in mind the productivity gains and other price reductions that the customer may request.

- Decision. If the cost-benefit and/or the detailed financial calculations look good, you can be sure that you will comply and still make money. Then, go for, confirm feasibility and send your price offer!

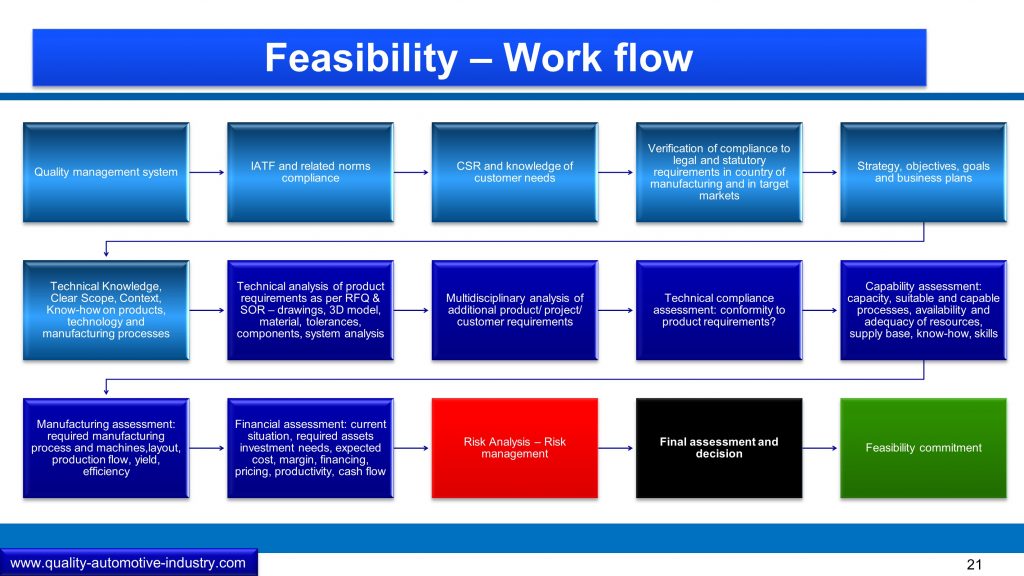

Take a look at the detailed flow shown below.

Feasibility commitment form

In case you need an excel file for your feasibility analysis and final confirmation or commitment, please find an excel file here: feasibility commitment

I hope you succeed in all your projects. Let me know if I could help you by providing this information. If you liked this post, subscribe to the newsletter and get the newest posts automatically!

Regards

Miguel

0 Comments