Quality Management Systems and the famous family ISO 9000

There is a huge advantage in the global standardization: regardless of your location in the world, your product, industry branch, etc. the requirements and certification rules for quality management systems remain the same. It was not always like that. I personally like the fact that I can audit quality management systems in many different plants, located in different countries, in different activity branches and with all kind of different products products and processes. It was not always like that…. Since the most important standard in the quality world of management systems is the ISO9001, we are going to dedicate some lines to the ISO9000 family and related standards. If you are new in quality systems you may want to read the post “what is a quality management system” before reading this article. I will show here the evolution of the ISO9000 family and the link to other standards.

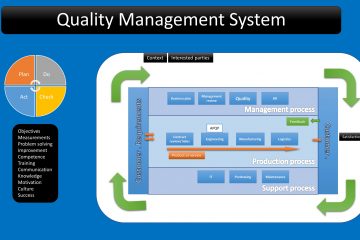

As you may remember, the ISO9001 defines a quality management system as “a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction”. The family ISO9000 is the set of standards issued originally to describe the terminology and scope of a quality management system, its requirements (depending on the main activities of the organization) and guidelines on how to plan, implement and improve the quality systems.

ISO 9000 – History

ISO9000 is a set of standards and guidelines for planning, implementing, managing and improving a quality management system. This set can be used or all kind of organizations regardless of product or service type, its physical location, etc. They all focus on the fulfilling of requirements and the customer satisfaction.

The ISO family (as we know it today) was fist published in 1987 based mainly on the series of BS 5750 and proposed to ISO in 1979. Originally, the idea was to define the requirements for the quality management system depending on the company type and and activity. The ISO9000 was the guide for selecting the base standard to fulfill, the ISO9001 was dedicated for companies with design and production activities, ISO9002 only for production and ISO9003 for inspection/testing and distribution. The ISO9004 was a guideline for quality management and quality system elements.

The ISO committee reviews periodically the standards. The first review of this family was made in 1994 but the big change came in 2000 when the ISO 9001-9003 were integrated in one standard: ISO9001. The ISO9004 changed the scope and became a guideline for performance improvements. Later on there were changes as shown in the next image.

ISO9001 Structure

Requirements

The ISO 9001 describes all the requirements for the quality management systems. These requirements need to be fulfilled so that the organization can get certified. The certification can be seen as a “proof” that the company not only has a system, focus on the customer needs and the product conformity but also aims for the customer satisfaction and continuous improvement. All the requirements are split in different chapters. Those chapters are exactly the same in all standards based on the ISO9001.

ISO9001 requirements – Quick reference

Introduction

1. Scope

2. Normative references

3. Terms and Definitions

4. Context of the organization

5. Leadership

6. Planning

7. Support

8. Operation

9. Performance evaluation

10. Improvement

Introduction

The chapters 1 to 3 provide hints, clarifications and definitions related to the quality management system and its purpose. For example, it reads that ” the decision to implement a QMS (quality management system) is a strategic decision for an organization that can help to improve its overall performance”. It also mentions the potential benefits of implementing a QMS:

- the ability to consistently provide products and services that meet customer and regulatory requirements.

- facilitating opportunities to enhance customer satisfaction.

- addressing risk and opportunities.

And of course, this standard is based on the quality management principles:

- customer focus,

- leadership

- engagement of people

- process approach

- improvement

- evidence-based decision making

- relationship management.

In the next post we will see in detail the main requirements of the ISO9001.

Subscribe to receive the new posts!

0 Comments