What do I need? One of them? All?

Prevention, correction or improvement?

And the answer is: it depends….

Nowadays all of them are considered as improvements. They are even called such in the ISO9001 and related standards. However, they are not exactly the same, nor can they be treated in the same way.

My personal definition of these three cases is:

- Correction is to solve an issue, problem or situation. For example, If your OEE (overall equipment efficiency) fell suddenly from 85% (monthly average) to 65%, you would certainly look for the cause of the bad results and make corrections.

- Prevention is to avoid or prevent something from happening, for example, an accident. Prevention may be the result of risk management techniques (like FMEA). Poka-yoke (error-proof), risk containment, readiness, reaction or emergency plans may be some of the results of prevention.

- Improvement is simply to become faster, stronger, or better in whatever it is that you have targeted to improve. It can also mean a reduction of waste, costs or development time.

Repair or rework?

In many cases we can correct a problem through repair, rework, etc

Risk management

One of the best quality strategies is to prevent problems rather than "correcting". For designing and manufacturing processes the FMEA is a very good option.

Improvement = better

Faster, better, more efficient, less expensive. If you go from 100% to 105% or more, you can be for sure be proud of your improvement.

It depends on the context or situation...

Is “Correction” consider an improvement? Well, perhaps in some cases. But it will depend on the perspective. If a new product had defects that lead to a zero functionality, the word “improvement” would never come to the mind of the consumer. For the consumer standpoint there was not even the required “quality”.

However if the manufacturer takes some actions to “correct” the process by solving the problem, there will certainly be an improvement for the future, for new consumers. Unfortunately there are many cases where things cannot be easily repaired or reworked. One of the worse consequences of a failure might be an accident which could have been prevented. In many cases material damage may be repaired but a life, health and some other assets may never be brought back to the original state. Therefore, the quality management systems focus more in risk management and the priority is always safety. The objective is to prevent whatever it is that can be prevented and/or be ready to react for whatever cannot be prevented.

When we think of the future, correcting the current problems is certainly an improvement. I can say that: Whenever possible we should try to prevent and if despite of the efforts, a problem appears we should try to correct it and to avoid recurrence. If we succeed in both, we will certainly get better.

Let’s keep then a mentality to develop a culture to get always safer, more efficient or simply said: better.

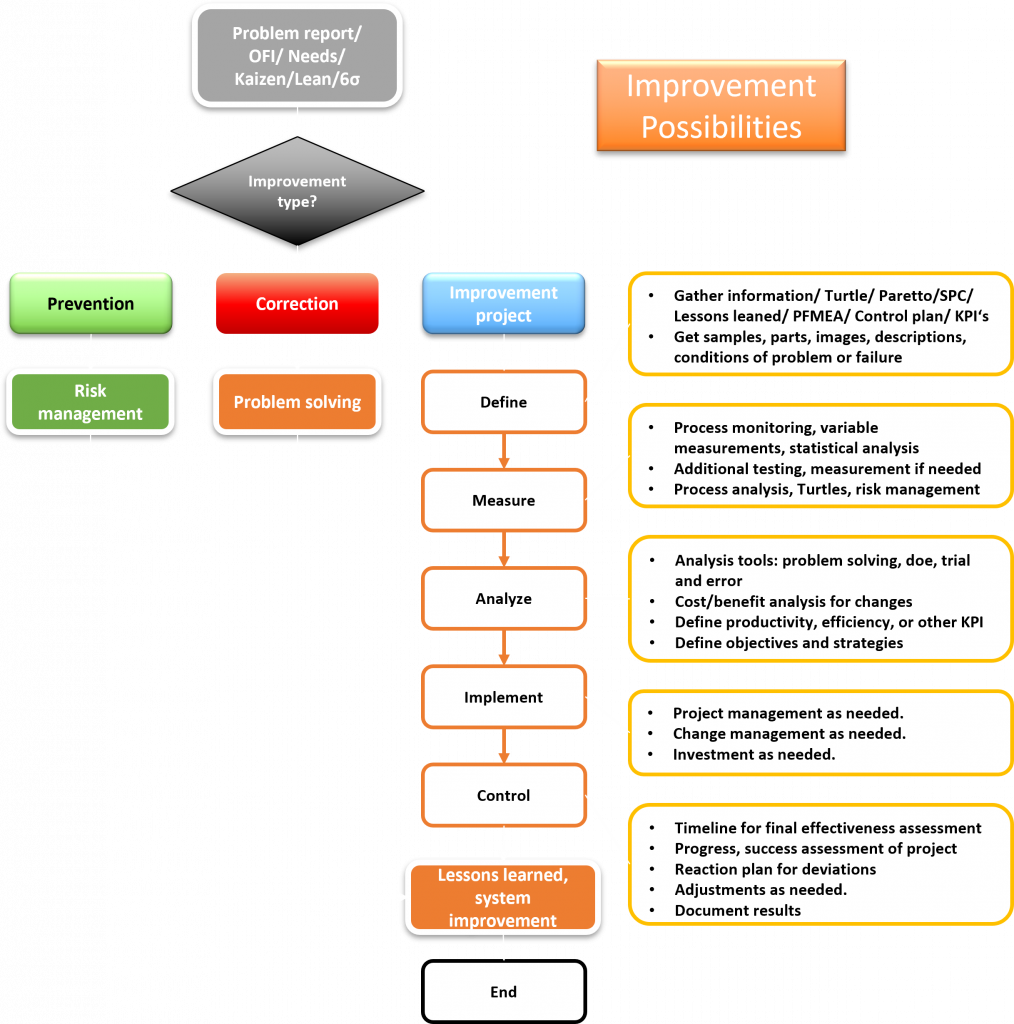

An easy approach to improvement projects

If you are trying to establish or improve your quality management system, perhaps you came already to the conclusion that an overall improvement process could be a good idea. The trigger can be one or several of the following options:

- Strategy.

- Customer claims, warranty.

- Nonconformities in your quality management system (deviations).

- Needs for improvement (goals for better profit, lower cost, higher productivity, etc).

- Risk management.

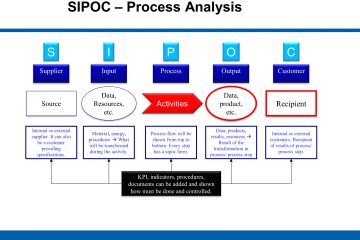

Some of the tools:

For product design and manufacturing processes you can/shall use FMEA.

For other business processes you can use any suitable technique for risk management for example, based on ISO31000.

A correction may be required upon customer claims, failures in the process, instability, high scrap, etc.

In the automotive industry the universal tool for problem solving is the 8D (eight disciplines) but there are many tools.

Some of them can be be used along with the 8D and support to:

- Identify or state the problem concisely and accurately.

- Quantify the problem or severity.

- Find the root cause or causes.

- Find correlation or interaction among causes.

- Assess and reproduce effects from root causes.

The main problem solving tools used in the automotive industry will be explained in the next articles.

In the automotive industry, as well as in many others there are always needs to improve. Safety of the systems, cost reduction, higher integration, better performance are always required.

When the decision to improve is made, you can always use one or more of the available techniques like:

- Kaizen

- Lean manufacturing

- Six sigma

- Process improvement

- Industrial engineering.

The choice will depend on the needs, scope, time, complexity, skills of the improvement team, etc.

The most common techniques will be covered in some of the next posts.

0 Comments