“Let's speak the same language”

MeaSurement system

Collection of gages, standards, operations, methods, personnel, environment and assumptions used to quantify a unit of measure to the characteristic being measured.

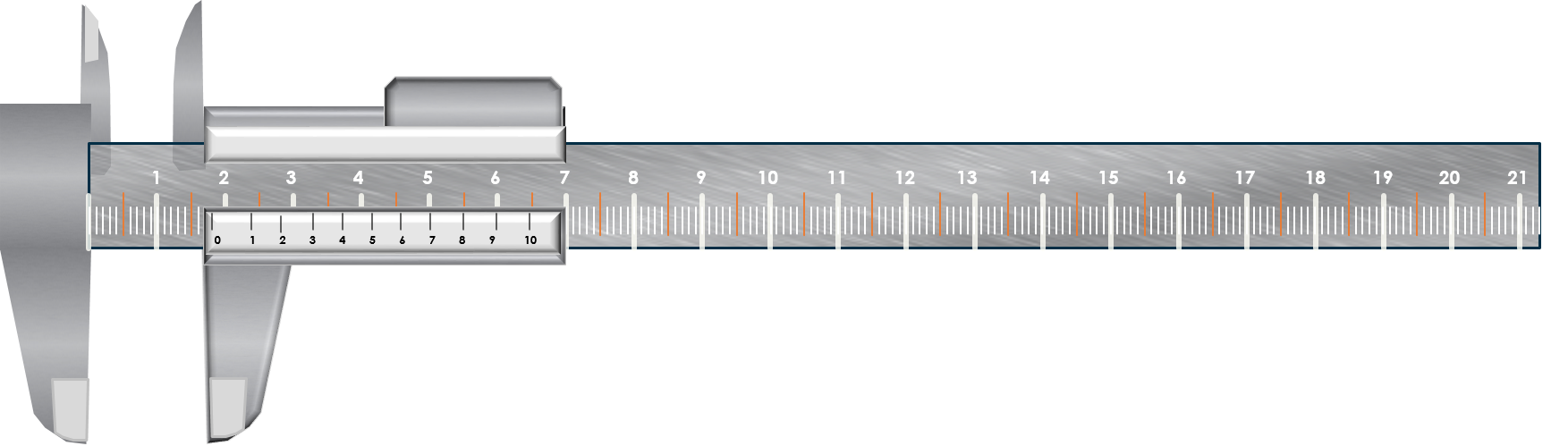

Gage

Device used to obtain measurements. A gage is also called measuring device or measuring instrument.

Measurand

Object, characteristic, parameter or phenomenon to be measured.

Standard

Accepted basis for comparison. It can also be called master, reference object, reference part or normal. The standard is the object or part which is used as the reference for a measurement because its value/magnitude is known and has been defined/confirmed through the measurement made by a recognized laboratory or institution.

Measurement

Assignment of values to a characteristic by using a scale and a reference for such values. Measurement can also be understood as a process of comparison of the magnitude of a measurand to a standard by using a measuring device.

Resolution

Also called discrimination, is the smallest readable unit of a gage. It is determined by the design and fabrication of the gage.

Accuracy

It is the proximity of a measurement or the average of several measurements to the reference value.

Precision

Proximity between measurements when the standard is measured. It can be understood as the “closeness” or “similarity” among all the measurements.

Bias

Bias is the “difference” or “distance” between the observed measurement and the standard (or reference value) or between the average value of all measurements and the standard.

Repeatability

Ability of a measurement system to provide similar (or very close) results when the same part is measured several times with the same gage and by the same appraiser.

reproducibility

Ability of the measurement system to provide similar or very close results when the same parts are measured by different appraisers.

Linearity

Changes in the magnitude of the Bias along the measuring range

Stability

Changes in the magnitude of the Bias during a period of time.

Calibration

Comparison of a measurement or a set of measurements obtained with a gage vs. the standard. Its objective is to find out the magnitude of the Bias. Linearity, measurement uncertainty and stability can also be part of the calibration process.

gage adjustment

Repair or maintenance to reduce or eliminate the discrepancy in the bias of a device (quantified through the calibration process).

Measurement system capability

The ability of a measurement system to provide reliable measurement information that enables the decision making process. The capability is normally calculated with indices that refer to the adequacy, measurement variations, deviations against the standard, repeatability and/or reproducibility of the system. In some cases, the measurement uncertainty is also a parameter. The capability can be assessed with one or more of the MSA techniques.

Why do I need to measure?

An important principle in quality is: We cannot control what we do not measure. In the production of products or services, the quality must be guaranteed; the customer specifications must be fulfilled and the expectations reached or exceeded. This is only possible by measuring and controlling the product characteristics, the process parameters or both.

Why must a measurement system be capable?

A measurement system has the objective not only to provide information but to enable the user to qualify products, processes and services as “good” or “bad” . If you can ensure that the product characteristics and process parameters are ok, you will deliver conforming goods and fulfill the customer requirements. If you can ensure that you will detect and segregate bad parts and correct the process as needed, your systems are working!

If the measurement system cannot accomplish its objective, you will not know whether bad parts are to be delivered to the customer or whether you scrap good parts. You will possibly incur in additional production and quality costs, have customer claims and high scrap, etc.

Only capable measurement systems provide reliable, consistent and adequate information to give you the certainty that your products and processes are within the specifications.

The car makers know this and therefore, they require all suppliers to use ONLY capable measurement systems.